Laminated Shims

LAMECO Laminated Shims, also called Peel Shims, Peelable Shims or Peel-Off Shims, are designed with special materials which have the property of being easily peelable into micro fine strips of a few hundredths of a millimeter / of two tenth thousands of an inch.

They are used to precisely fill space between components, to achieve the truest possible fit within mechanical assemblies.

Any complex mechanical assembly suffers from the accumulated faults created by machining tolerances. This is why clearances of several thousandths of an inch will be found once the assembly is completed. These clearances must be compensated in order for the assembly to fulfill its intended function.

The LAMECO laminated shim can be easily peeled with a simple scalpel.

Before the invention of laminated shims, technicians could only resort to one of two methods, which today Lameco has rendered obsolete, to correct unacceptable clearances:

Grinding of adjustment shims

Principle: after measuring the clearance needing to be compensated, the technician resorts to a grinding process in order to manufacture 'adjustment shims'.

Disadvantage: this process is wasteful of time, money, and resources. It requires the purchase of a grinding machine, and the use of highly skilled (and costly) technicians. It also adds an extra stage to the manufacturing process.

Stacking of solid shims

Principle: starting as before - and measuring the clearance needing to be compensated, technicians stack thin metal sheets, inserted with difficulty into often almost inaccessible places.

Disadvantage: this method risks dangerous imprecision. Due to residual matter such as dust, grease and material chips which get in during the creation of the stack, any precision of the end result becomes very hit and miss.

Laminated shims are invaluable design and assembly tools that replace the inefficient techniques of the past to achieve superior accuracy.

For more information on laminated shim please visit our F.A.Q. page.

The advantages of LAMECO laminated shims

LAMECO laminated shims save time, improve on precision, and do away with downtime at the grinding machine. They provide our customers with an excellent quality to price ratio.

Speed and Simplicity

- LAMECO laminated shims can be peeled with scalpel or forefinger (peel shims in INTERCOMPOSITE®, DUOPEEL®, COBRA.X®, PEEKPEEL®, X.FIBER® X.FIBER HIGH-DENSITY®)

- No need for special tools

- Quick production line adjustments and field repairs

- Instantaneous compensation for play or wear and tear without production stoppages

- Avoids machine reworking

- Allows level adjustment without taking the machine apart

Savings

- LAMECO laminated shims reduce assembly time

- Eliminate need for grinding and

- Eliminate need of solid shims stocks

Flexibility

- They satisfy standards in wide range of industrial machine and assembly line applications.

Precision

- They guarantee optimal precision (which pilings cannot achieve in any way.)

The LAMECO Specialty: Impeccable Quality

- Each individual layer of our laminated shims, including all of the laminated shims in our INSTANT-PEEL® range, is bonded to the next across its entire surface and not just at the edges.

- Furthermore, thanks to our proprietary production processes, they are perfectly flat and entirely devoid of burrs - whether made of metal or composite material.

X.Fiber®

- Extremely Light

- Impressive mechanical properties

- Endurance comparable with laminated metals

- Anti-fretting

- Manually peelable without tools

- No risk of finger cuts

- Economical in use

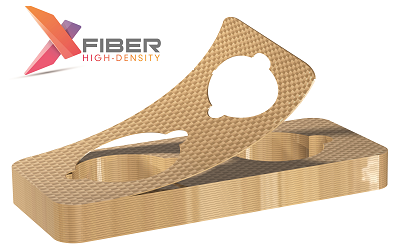

X.FIBER HIGH-DENSITY®

- Very Light

- Impressive mechanical and chemical properties

- Endurance comparable with laminated metals

- Anti-fretting

- Manually peelable without tools

- No risk of finger cuts

- Economical in use

INTERCOMPOSITE®

- Very Light

- Good physical, mechanical, thermal and chemical characteristics

- Anti-fretting

- Manually peelable without tools

- No risk of finger cuts

- Adaptable to curved profiles

- Low Cost

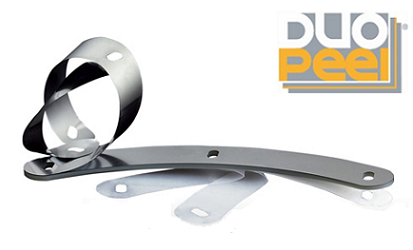

DUOPEEL®

- Easily differentiate the different thicknesses of a bi-laminate shims

- Very Light

- Good physical, mechanical, thermal and chemical characteristics

- Easy and safe to peel

- Adaptable to curved profiles

INSTANT-PEEL®

- Ease of peeling and rapidity of use

- Optimum accuracy, no burrs

- Safety, no risks of accident

- The metal’s good physical, mechanical, thermal and chemical characteristics are preserved

- Intelligent and economical

CURVPEEL®

- Highly accurate curved shims with one or more constant radii

- Perfect fit on curved bodies

- No extra fittings/adjustments being required

- Gain in time / Financial benefit

SILENTLINE®

- Reduction and lateral dispersion of medium/high vibration frequencies of around 50%

- Improved mechanical properties

- Benefits of reduced maintenance

QAR.X DATA-SHIM®

- Security: all Lameco shim data is encoded onto the chip buried within the laminated stack, avoiding any risk of paper loss

- Paperless documentation achieved! Part history in its entirety can be recorded on the chip

- Obviates the need for stamp-marking of parts

- Simplifies the inspection, acceptance and storage operations

| Material | Specific Weight | Weight-saving | |

|---|---|---|---|

| X.FIBER-Glass® X.FIBER HIGH-DENSITY® |

X.FIBER-Carbon® | ||

| X.FIBER-Carbon® | 1.05 | - | - |

| X.FIBER-Glass® X.FIBER HIGH-DENSITY® |

1.35 | - | 1.29 x |

| Steel | 8.2 | 6.07 x | 7.81 x |

| Brass | 8.5 | 6.3 x | 8.1 x |

| Material | Specific Weight | Weight-saving |

|---|---|---|

| INTERCOMPOSITE® | 1.395 | |

| Aluminum | 2.8 | 2.01 x |

Let us recap

So you’re looking for Peelable Shims?

- Truly Peelable?

- Without any burrs, a flawless finish that minimizes any risk of cuts?

- With entirely reliable delivery times, which on request are the fastest in the industry?

- Which guarantees precision to a few hundredths of a millimeter / four tenth thousands of an inch when needed.

Choose LAMECO!