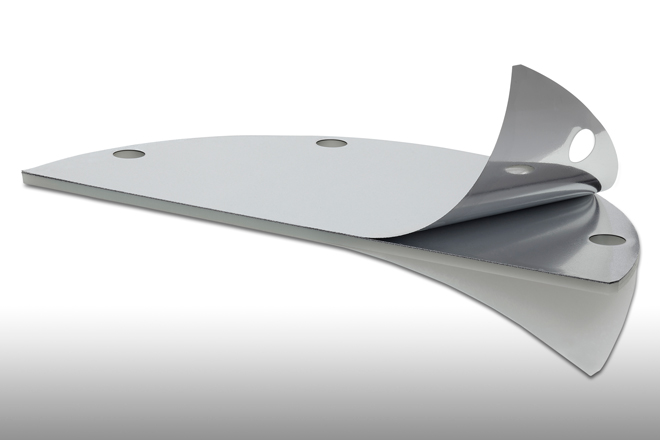

DUOPEEL® Bilaminated Shims

DUOPEEL® is a bilaminate (bi-laminated) material designed by LAMÉCO. This peel-off (bi-laminated) composite material allows the different hand peelable layers to be easily differentiated. One of the two materials has received a very thin covering layer of aluminium giving it a metallic appearance.

This makes it easy to identify the different peelable parts of your finished product. You can peel the appropriate side off to obtain the desired shim thickness.

Benefits Physical & Mechanical Characteristics Lamination Thicknesses

Benefits of DUOPEEL® peelable bilaminate shims

Easy identification of the different peelable sections

For example, a peel-off shim with a total thickness of 1.75 mm / .07" can be made of a section of 10 elements of polyethylene glycol terephthalate of 0.075 mm / .003" and a second of 40 sheets of metallized polyester of 0.025 mm /.001".

Lightness

It is an appropriate response to a requirement for lighter materials (to achieve greater autonomy or payload). DUOPEEL® is, with INTERCOMPOSITE®, COBRA.X®, X.FIBER® and X.FIBER HIGH-DENSITY®, the lightest of all peelable materials.

| Material | Specific Weight | Weight-saving |

|---|---|---|

| DUOPEEL® | 1.395 | |

| Aluminum | 2.8 | 2.01 x |

Good physical, mechanical, thermal and chemical characteristics

DUOPEEL® has a thermal resistance that is equivalent to that of aluminum while being twice as light! (see the specifications table below).

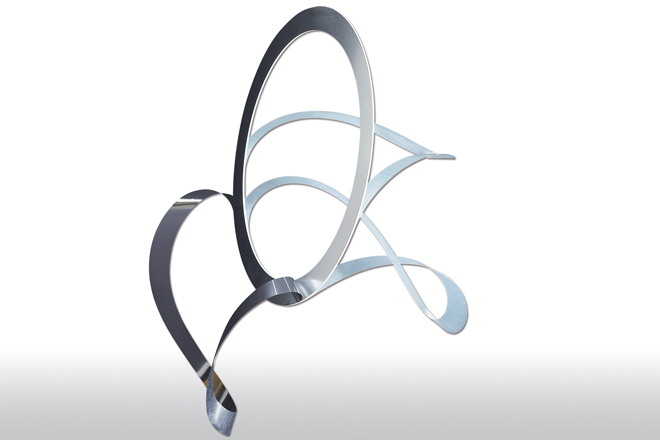

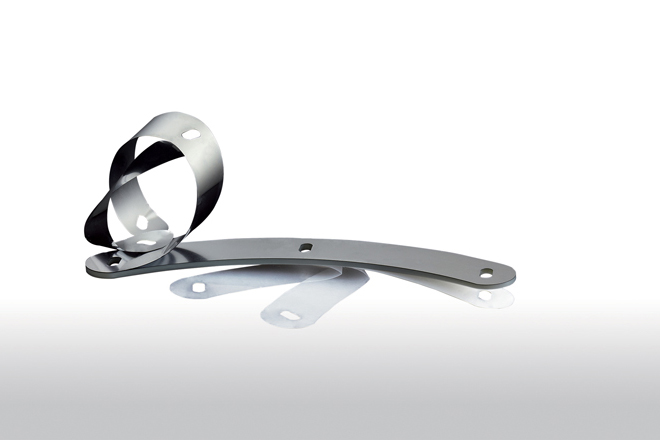

Adapts to curved shapes

DUOPEEL® immediately adapts to most curves without any loss of precision. And all this at the assembly site itself.

Ease and speed of use

DUOPEEL® can be peeled by finger, there's no need for tools.

Safety, no risk of occupational accidents

This composite material removes any risk of injury during the peeling operation.

Savings and economy

Once peeled, the sheets remain fl at and show no signs of deformation. They can thus be re-used and can serve as single-unit shimming parts.

DUOPEEL® Physical & Mechanical Characteristics

| Properties | Values | Units |

|---|---|---|

| Density | 1.395 | |

| Comprensive Fracture Strength Limit | 600 | MPa |

| Resin Temperature Resistance * | 266 130 |

°F °C |

* The Shim use is not affected by the possible disappearance of the resin, under the heat action.

Thicknesses available for DUOPEEL® bilaminated shims

| Standard | Thicknesses of laminations in mm / inches Standard |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Polyethylene Glycol Terephthalate | Metallized polyester | |||||||||||

| 0,012 .0005 |

0,019 .0007 |

0,023 .0009 |

0,025 .001 |

0,05 .002 |

0,075 .003 |

0,1 .004 |

0,2 .008 |

0,012 .0005 |

0,019 .0007 |

0,023 .0009 |

0,05 .002 |

|

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | 11 | 3 | 4 | 5 | 7 | |

| LS12 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| LS13 | √ | √ | √ | √ | ||||||||