Composite Laminated Shims

LAMÉCO high-tech peelable shims come in a wide choice of composite laminated materials:

Glass or Carbon Fabric Peel Shim

- Extremely Light

- Impressive mechanical properties

- Endurance comparable with laminated metals

- Anti-fretting

- Manually peelable without tools

- No risk of finger cuts

- Economical in use

High-Resistance Glass Fabric Peel Shim

- Very Light

- Impressive mechanical and chemical properties

- Endurance comparable with laminated metals

- Anti-fretting

- Manually peelable. No risk of finger cuts

- Economical in use

PETG Laminated Shim

- Very Light

- Good physical, mechanical, thermal and chemical characteristics

- Anti-fretting

- Manually peelable without tools

- No risk of finger cuts

- Adaptable to curved profiles

- Low Cost

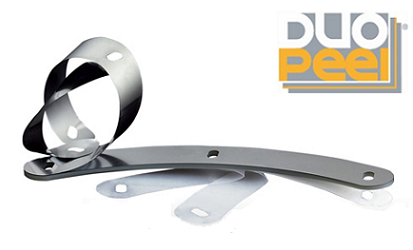

Bilaminated Shim

- Easily differentiate the different thicknesses of a bi-laminate shims

- Very Light

- Good physical, mechanical, thermal and chemical characteristics

- Easy and safe to peel

- Adaptable to curved profiles

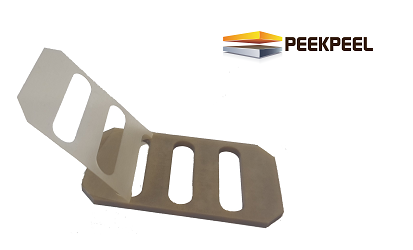

PEEK Laminated shim

- High thermal resistance

- Very Light

- Ease of peeling and rapidity of use

- Safety, no risks of accident

- Anti-Fretting

And also in polyimide according to the specification AMS-DTL-22499.

Scroll down to discover our wide choice of lamination thicknesses.

You can find at the end of this page the physical and mechanical characteristics of each of our laminated composites. Do not hesitate to contact us if you need any further information. We will be happy to help.

Our composite laminated shims can be manufactured with the following options

Nonplannar Laminated Shims

- Highly accurate folded, conic or curved laminated shims

- Perfect fit wihtout delamination

- No extra fittings/adjustments being required

- Gain in time / Financial benefit

Laminated Shim with Chip

- Security: all LAMÉCO shim data is encoded onto the chip buried within the laminated stack, avoiding any risk of paper loss

- Paperless documentation achieved! Part history in its entirety can be recorded on the chip

- Obviates the need for stamp-marking of parts

- Simplifies the inspection, acceptance and storage operations

Self-Adhesive Laminated Shim

- The shim stays in place on its own

- Indispensable when screws cannot be used

- Long term adhesion

Available Laminated Composites & Thicknesses

| LAMÉCO Standard / Materials | Standard | Thicknesses of laminations in mm / inches Standard | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0,005 .0002 |

0,01 .0004 |

0,012 .0005 |

0,019 .0007 |

0,023 .0009 |

0,025 .001 |

0,05 .002 |

0,075 .003 |

0,1 .004 |

0,11 .0043 |

0,2 .008 | |||

| INTERCOMPOSITE® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| LS12 | Polyethylene Glycol Terephthalate | ISO 15988 | √ | √ | √ | √ | √ | √ | √ | √ | |||

| DUOPEEL® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| LS13 | Metallized Polyester | √ | √ | √ | √ | ||||||||

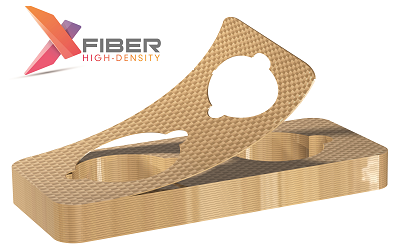

| X.FIBER® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| LS15 | Carbon Fabric | √ | |||||||||||

| LS16 | Glass Fabric | √ | √ | √ | |||||||||

| COBRA.X® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| LS17 | BCRW Fabric | √ | |||||||||||

| PIMYX® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| LS20 | Polyimide | AMS-DTL-22499/6 | √ | ||||||||||

| X.FIBER HIGH-DENSITY® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| LS21 | High-performance Glass Fabric | √ | |||||||||||

| PEEKPEEL® | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||

| LS22 | PolyEtherEtherKetone | √ | √ | √ | √ | √ | √ | √ | √ | ||||

Physical & Mechanical Characteristics of our Laminated Composites

| LAMÉCO Standard | Materials | Density | Comprehensive Fracture Strength Limit | Resin Temperature Resistance (2) |

|---|---|---|---|---|

| LS12 | INTERCOMPOSITE® Polyethylene Glycol Terephthalate |

1.395 | 600 MPa | 130°C / 266°F |

| LS13 | DUOPEEL® Metallized Polyester |

1.395 | 600 MPa | 130°C / 266°F |

| LS15 | X.FIBER® Carbon Fabric |

1.05 | 1 570 MPa | 300°C / 572°F |

| LS16 | X.FIBER® Glass Fabric |

1.35, 1.37 or 1.39 (depending on thickness) | 1 900 MPa (1) | 370°C / 698°F |

| LS17 | COBRA.X® BCRW Fabric |

1 | - | - |

| LS20 | PIMYX® Polyimide |

1.42 | - | - |

| LS21 | X.FIBER HIGH-DENSITY® High-performance Glass Fabric |

1.35 | - | - |

| LS22 | PEEKPEEL® PolyEtherEtherKetone |

1.3 | - | - |

(1) Physical limit of the test machine = no fracture.

(2) The Shim use is not affected by the possible disappearance of the resin, under the heat action.