Metallic Laminated Shims

Wide choice of laminated metals and grades

LAMÉCO peelable laminated shims come in a wide choice of thicknesses and laminated metals: aluminium, brass, steel, stainless steel and titanium. Check our table here below for more details. If you do not find the thickness you need among the laminated metals we propose, have a look at our composite laminated materials. Most of them offer mechanical, physical and/or thermal characteristics similar or better to the metal ones.

Customer choice of peeling strength

Good to know: the peeling strength of LAMÉCO laminated metals can be fine tuned to your requirements.

Custom or standard laminated shims

Our laminated shims are manufactured according to customer drawings or requirements or according to standards such as AMS-DTL-22499, LN29557, DIN 988...

Exclusive and unique laminated shims

LAMÉCO has developed four products in the field of metal laminated shims:

Easily Peelable Shim

- Ease of peeling and rapidity of use

- Optimum accuracy, no burrs

- Safety, no risks of accident

- The metal’s good physical, mechanical, thermal and chemical characteristics are preserved

- Intelligent and economical

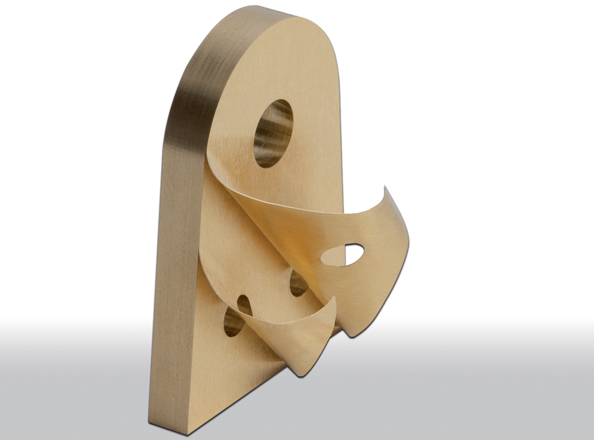

Nonplannar Laminated Shims

- Highly accurate folded, conic or curved laminated shims

- Perfect fit wihtout delamination

- No extra fittings/adjustments being required

- Gain in time / Financial benefit

Noise Abatement Peel Shim

- Reduction and lateral dispersion of medium/high vibration frequencies of around 50%

- Improved mechanical properties

- Benefits of reduced maintenance

Self-Adhesive Laminated Shim

- The shim stays in place on its own

- Indispensable when screws cannot be used

- Long term adhesion

Available Laminated Metals & Thicknesses

| Standard / Materials | Standard | Thicknesses of laminations in mm / inches Standard | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STD | AISI SAE |

UNS | EN | BS | ISO | 0,01 .0004 |

0,025 .001 |

0,05 .002 |

0,075 .003 |

0,1 .004 |

0,2 .008 | |

| Aluminum | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| LS1 | 1200 | A91200 | 1200 | 1200 | Al99,0 | EN 573-3, EN 546-2, AMS-DTL-22499/1, LN29557-3 | √ | √ | ||||

| LS2 | 5052 | A95052 | 5052 | 5052 | AlMg2,5 | √ | √ | |||||

| LS18 | 1050 | A91050 | 1050 | 1050A | Al99,5 | √ | √ | √ | ||||

| LS19 | 1100 | A91100 | 1100 | 1100 | Al99,0Cu | √ | √ | |||||

| brass | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| LS3 | C27200, C27700 | CuZn37 | CZ108 | CuZn37 | AMS-DTL-22499/2, LN29557-2 | √ | √ | √ | √ | |||

| Stainless Steel | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| LS4 | 302 | S30200 | 1.4300, 1.4310 | 304S31 | EN 10088-1, EN 10088-2, AMS-DTL-22499/3, LN29557-1 | √ | √ | √ | ||||

| LS5 | 304 | S30400 | 1.4301 1.4350 |

304S15 304S16 |

√ | √ | √ | √ | √ | |||

| LS6 | 304L | S30403 | 1.4306 | 304S11 | √ | √ | √ | |||||

| LS7 | 316 | S31600 | 1.4401 1.4036 |

316S16 316S33 |

√ | √ | ||||||

| LS8 | 316L | S31603 | 1.4404 1.4435 |

316S12 316S13 |

√ | √ | √ | |||||

| Steel | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| LS9 | 1010 | G10100 | 1.1121 | 040A10 | 1010 | EN 10084, AMS-DTL-22499/4, SAE AMS 6387 | √ | √ | √ | √ | ||

| Titanium | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| LS10 | Ti Gr1 | R50250 | 3.7025 | 2TA1 | 5832-2 | AMS-DTL-22499/5, ASTM B 265 | √ | √ | √ | |||

| LS11 | Ti Gr2 | R50400 | 3.7035 | TA 2 | 5832-2 | √ | √ | √ | √ | |||

| brass in INSTANT-PEEL® | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| IPLS3 | C27200, C27700 | CuZn37 | CZ108 | CuZn37 | √ | √ | √ | √ | ||||

| Stainless Steel in INSTANT-PEEL® | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| IPLS4 | 302 | S30200 | 1.4300, 1.4310 | 304S31 | √ | √ | √ | |||||

| IPLS5 | 304 | S30400 | 1.4301 1.4350 |

304S15 304S16 |

√ | √ | √ | √ | √ | |||

| IPLS6 | 304L | S30403 | 1.4306 | 304S11 | √ | √ | √ | |||||

| IPLS7 | 316 | S31600 | 1.4401 1.4036 |

316S16 316S33 |

√ | √ | ||||||

| IPLS8 | 316L | S31603 | 1.4404 1.4435 |

316S12 316S13 |

√ | √ | √ | |||||

| Steel in INSTANT-PEEL® | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| IPLS9 | 1010 | G10100 | 1.1121 | 040A10 | 1010 | √ | √ | √ | √ | |||

| Titanium in INSTANT-PEEL® | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| IPLS10 | Ti Gr1 | R50250 | 3.7025 | 2TA1 | 5832-2 | √ | √ | √ | ||||

| IPLS11 | Ti Gr2 | R50400 | 3.7035 | TA 2 | 5832-2 | √ | √ | √ | √ | |||

| Stainless Steel in SILENTLINE® | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| SLS4 | 302 | S30200 | 1.4300, 1.4310 | 304S31 | √ | √ | √ | |||||

| IPLS5 | 304 | S30400 | 1.4301 1.4350 |

304S15 304S16 |

√ | √ | √ | √ | √ | |||

| SLS6 | 304L | S30403 | 1.4306 | 304S11 | √ | √ | √ | |||||

| SLS7 | 316 | S31600 | 1.4401 1.4036 |

316S16 316S33 |

√ | √ | ||||||

| SLS8 | 316L | S31603 | 1.4404 1.4435 |

316S12 316S13 |

√ | √ | √ | |||||

| Steel in SILENTLINE® | 2 | 6 | 7 | 8 | 9 | 11 | ||||||

| SLS9 | 1010 | G10100 | 1.1121 | 040A10 | 1010 | √ | √ | √ | √ | |||

If you have not found the thickness you need, have a look at our composite laminated materials. Most of them offer mechanical, physical and/or thermal characteristics similar or better to the metal ones.